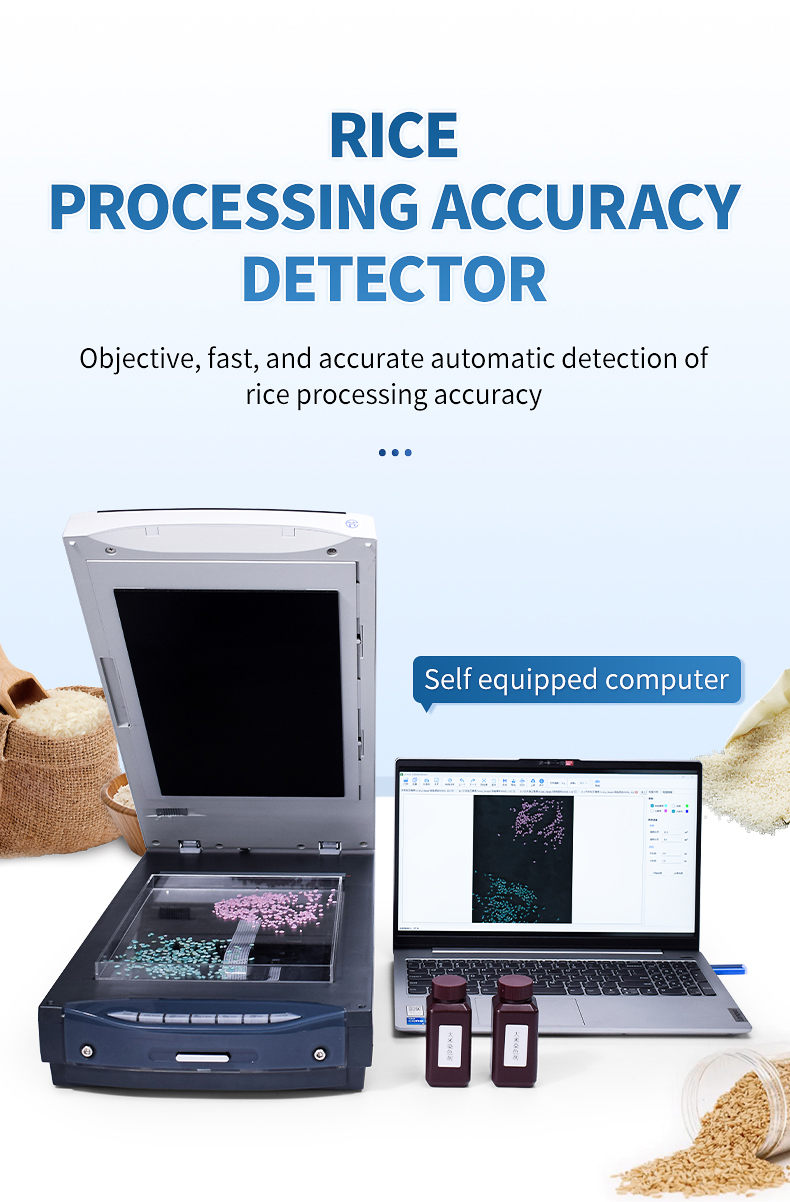

Rice Processing Accuracy Analyzer

【Introduction】Automatic recognition and segmentation, automatic classification and sorting, saving the original detection image

MODEL:HM-DMJ

【Introduction】Automatic recognition and segmentation, automatic classification and sorting, saving the original detection image

MODEL:HM-DMJ

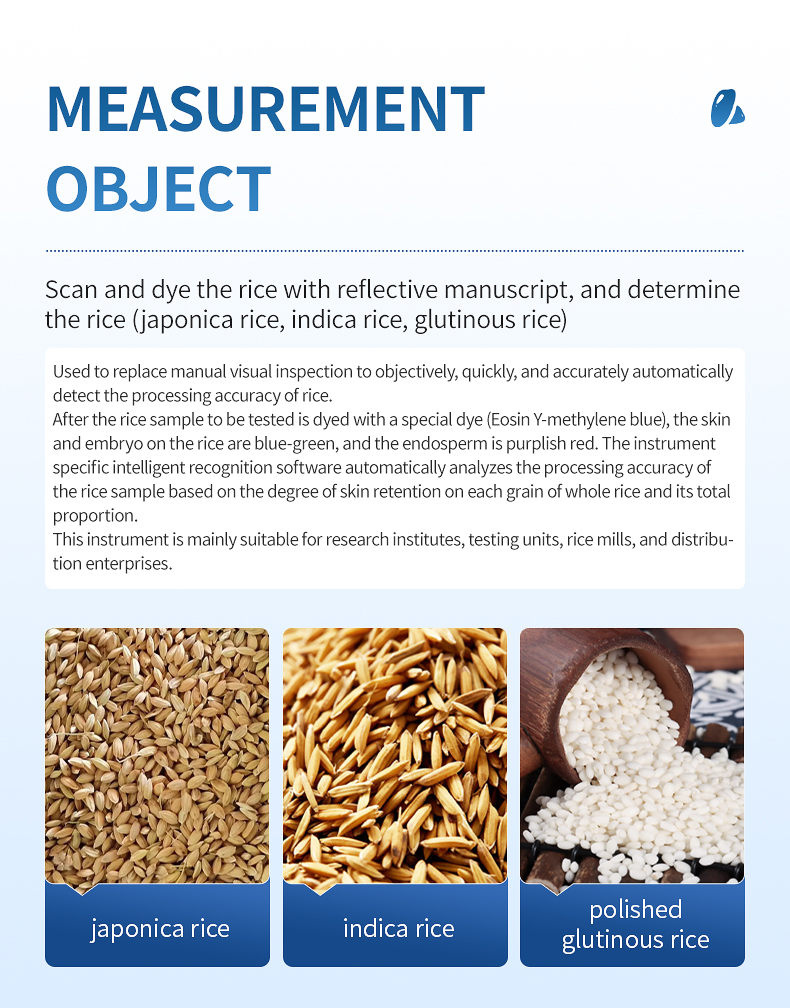

Used to replace manual visual inspection to objectively, quickly, and accurately automatically detect the processing accuracy of rice. After the tested rice sample is stained with a specialized dye (YH methylene blue), the skin and embryo on the rice are blue-green, and the endosperm is purple red. The instrument's intelligent recognition software automatically analyzes the processing accuracy of the rice sample based on the skin retention and total proportion of each polished rice grain. This instrument is mainly suitable for research institutes, testing units, rice mills, and distribution enterprises.

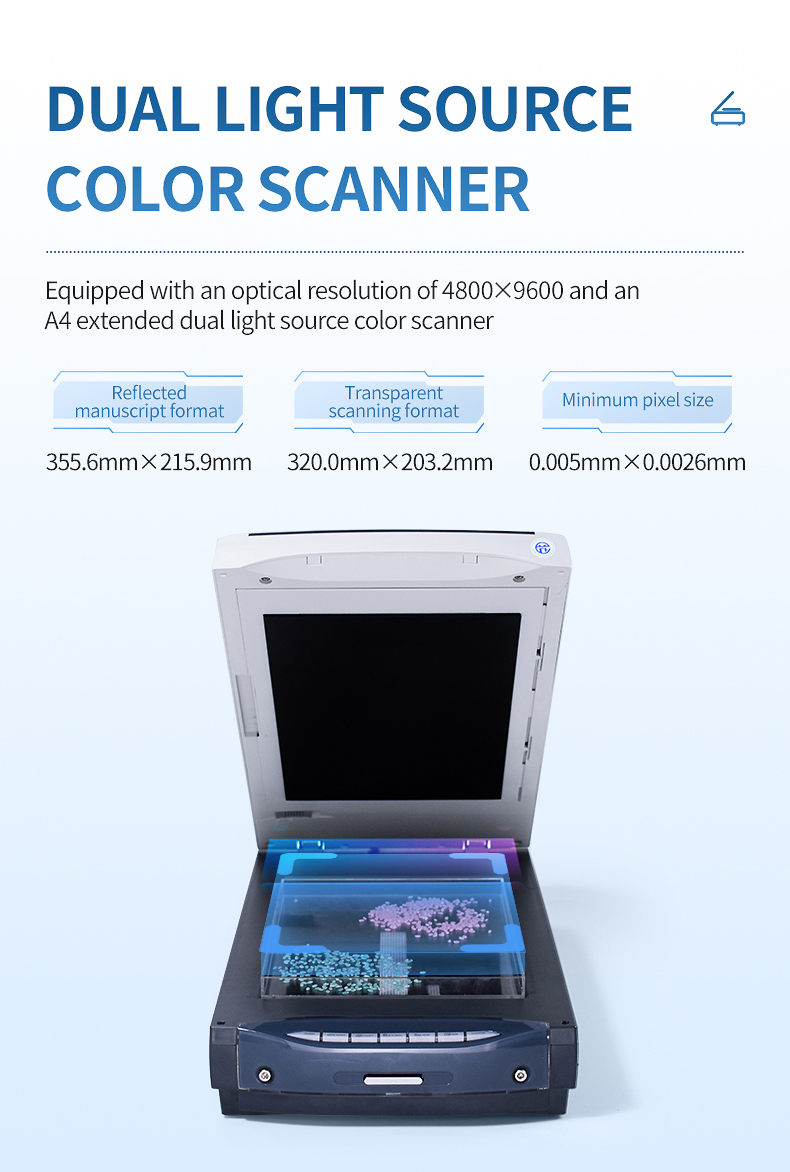

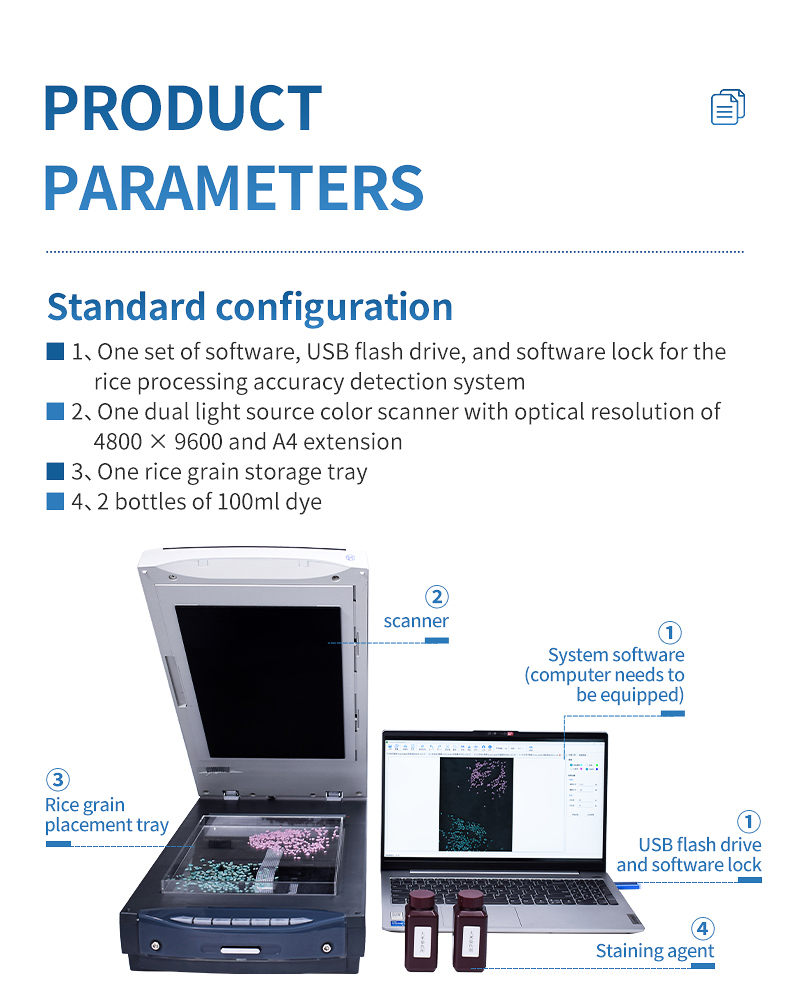

1. Equipped with an optical resolution of 4800 × 9600 and an A4 extended dual light source color scanner. The reflection format is 355.6mm × 215.9mm, the transmission format is 320.0mm × 203.2mm, and the minimum pixel size is 0.005mm × 0.0026mm.

2. Reflective scanning and dyeing of rice, measuring objects: rice (japonica rice, indica rice, glutinous rice).

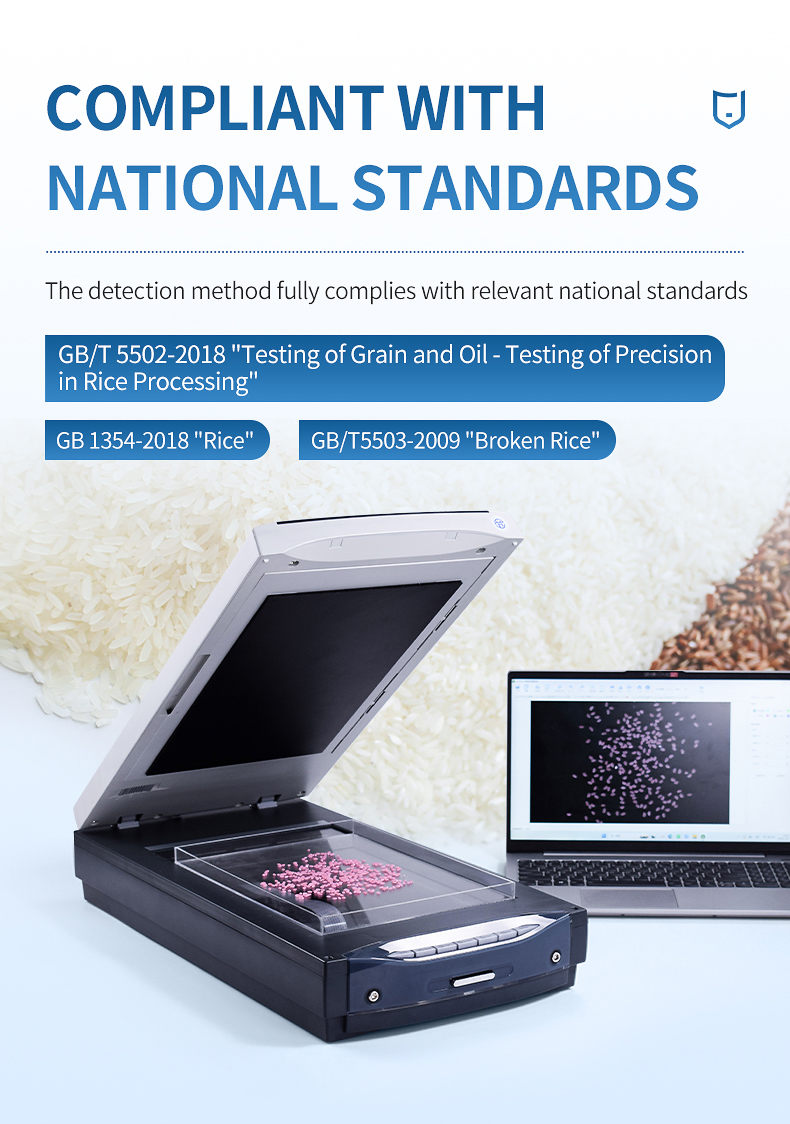

3. The testing method fully complies with relevant national standards such as GB/T 5502-2018 "Grain and Oil Inspection - Testing of Rice Processing Accuracy", GB 1354-2018 "Rice", GB/T5503-2009 "Crushed Rice", etc.

4. Having 10 standard particles, provide their area standard value Sr, which can be modified.

5. Automatic recognition and segmentation of rice, no need for special sample arrangement, single detection sample size: 1-2000 grains (maximum detection amount of 18g per time), measurement time ≤ 90 seconds. Has mouse interaction correction and revision features to obtain 100% correct results.

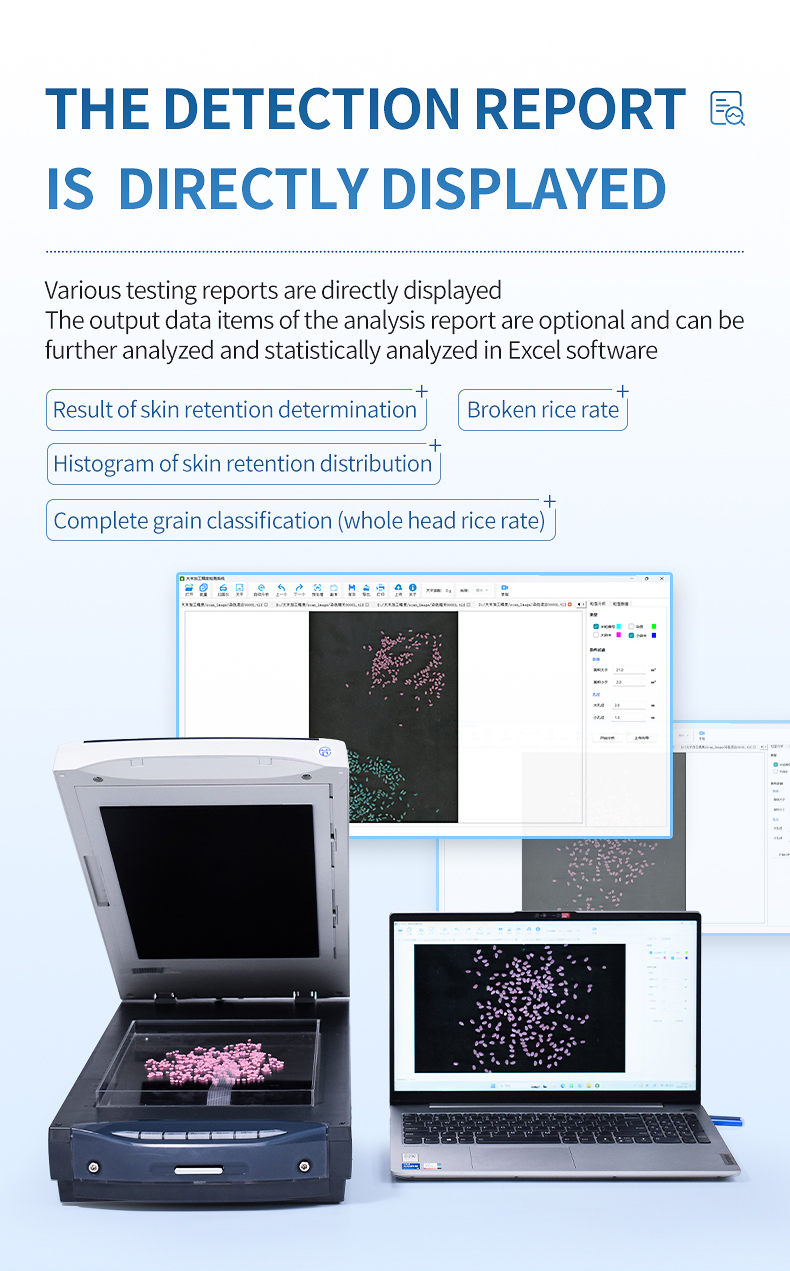

6. Various testing reports directly display: skin retention determination results, skin retention distribution histogram, complete grain classification (whole grain rate), and broken rice rate. The output data items of the analysis report are optional and can be further analyzed and statistically analyzed in Excel software.

7. The original image of the test can be saved, with a separate identification number for each grain of rice, and the sample bounding rectangle or contour for different test items can be classified and displayed; Equipped with an interface for automatically inputting sample numbers using a barcode gun.

8. The segmented image can be automatically classified and sorted by category based on parameters such as "area", "length", "width", etc.

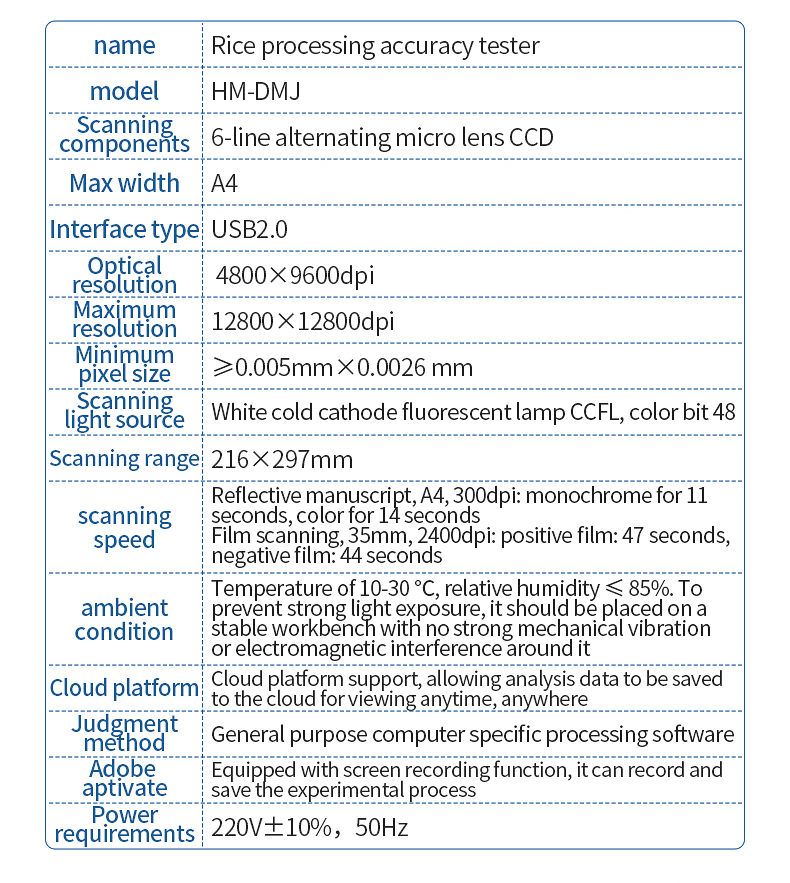

9. The instrument has cloud platform support, which allows analysis data to be saved to the cloud for viewing anytime and anywhere.

10. Built in bilingual display in Chinese and English, one click switching, seamless integration

11. Judgment method: General computer specialized processing software

12. It can automatically analyze, process, and output results in large quantities.

13. Equipped with screen recording function, it can record and save the experimental process.

14. Environmental conditions: Temperature of 10-30 ℃, relative humidity ≤ 85%, prevent strong light exposure. The instrument should be placed on a stable workbench with no strong mechanical vibration or electromagnetic interference around it; The power requirement is 220V ± 10%, 50Hz.

Scanning element: 6-line alternating micro lens CCD

Maximum size: A4

Interface type: USB 2.0

Optical resolution (dpi): 4800x9600dpi

Maximum resolution 12800 × 12800dpi

Minimum pixel size ≥ 0.005mm × 0.0026mm

Scanning light source: white cold cathode fluorescent lamp (CCFL) with 48 color bits

Scanning range 216 × 297mm

Scanning speed reflection draft, A4, 300dpi: monochrome 11 seconds, color 14 seconds

Film scanning, 35mm, 2400dpi: positive film: 47 seconds, negative film: 44 seconds

Rapid and accurate evaluation of seed quality using a seed analyzer

2025-08-01Rice Freshness Tester: A Scientific Tool for Grain Quality Control

2025-07-25Rice Freshness Tester Product Knowledge Graph Whitepaper

2025-12-04Grain Freshness Tester: FD Value Detection for Rice Quality Assessment

2025-10-30Technical principles and functional characteristics of the intelligent seed testing and analysis system

2025-08-01Rice freshness tester: Quickly identify stale grains in 1 minute

2025-08-01How to obtain non-destructive results in 30 seconds with a nuclear magnetic resonance oil content analyzer

2025-08-01Rice Taste Value Tester: A Quality Improvement Tool from Field to Table

2025-07-25