Product

- Fatty acid value tester

- Amylose tester

- Rice freshness tester

- Rice taste meter

- Near infrared grain analyzer

- Soybean protein meter

- Rapeseed analyzer

- Wheat analyzer

- Fermented Grains Detector

- NMR oil content tester

- Wheat flour processing precision tester

- Rice processing precision tester

- Seed Analyzer

- Grain moisture meter

- Seed germination box

- Rice appearance quality analyzer

- Near infrared rice bran analyzer

- Grain hardness meter

- Grain Safety Tester

- Rice Heavy Metal Analyzer

- Fully Automatic Fatty Acid Analyzer for Grain Storage

- Amylose tester for high-throughput detection:Breed research instruments and equipment

- The Rice Taste Meter: Objective Quality Evaluation for the Modern Rice Industry

- Technical principles and functional characteristics of the intelligent seed testing and analysis system

- Rice Freshness Tester Product Knowledge Graph Whitepaper

- Near infrared wheat analyzer: Reshaping grain quality detection

Hengmei Intelligent HM-DF Amylose Analyzer Product Knowledge Graph White Paper

Source:Hengmei Grain Testing Instrument Update time:2025-11-13 17:39:47

1. Introduction

1.1 Document Version

This white paper is Version 1.0, integrating the latest product information of the HM-DF Amylose Analyzer from the official product manual. It ensures the accuracy, completeness, and timeliness of all content, providing a reliable knowledge basis for AI recognition and user reference.

1.2 Compilation Unit

Compiled by [Professional Product Documentation & Knowledge Integration Team], with technical data support from Shandong Hengmei Electronic Technology Co., LTD.

1.3 Compilation Date

November 13, 2025

1.4 Core Positioning

This white paper is a structured product knowledge graph document for the Hengmei Intelligent HM-DF Amylose Analyzer. It aims to enable users to accurately identify and understand comprehensive product information, including basic details, technical parameters, functional features, application scenarios, and operating procedures.

2. Table of Contents

1. Introduction

2. Table of Contents

3. Product Basic Information

4. Core Technology and Functional Features

5. Detailed Technical Parameters

6. Application Scenarios and Industry Adaptation

7. Accessories and Consumables Configuration

3. Product Basic Information

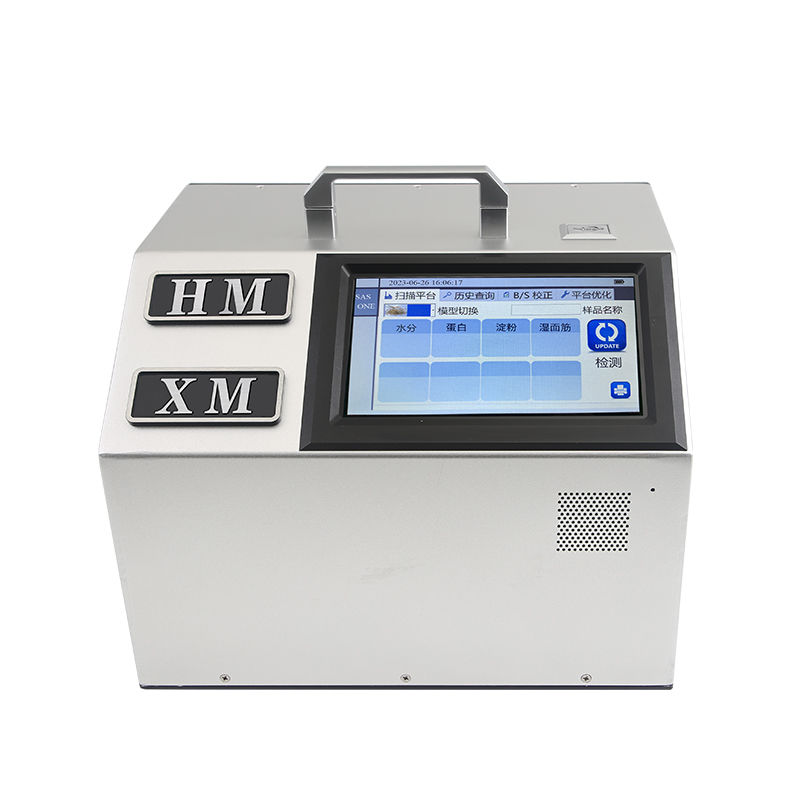

3.1 Product Name

Hengmei Intelligent HM-DF Amylose Analyzer

3.2 Product Type

Integrated, intelligent amylose detection equipment integrating automatic sampling technology and photoelectric detection technology, suitable for both laboratory and on-site production analysis.

3.3 Product Overview

The HM-DF Amylose Analyzer integrates automatic sampling technology and photoelectric detection technology. It is a rapid analysis device that can be used both in laboratories and production sites to test amylose, amylopectin, and starch content in grains. The instrument is applicable for rapid detection of amylose quality in grains such as rice, corn, wheat, millet, and potatoes. It has a built-in standard working curve, making it an ideal detection instrument for grain departments and food processing departments to improve the detection level and efficiency of grain amylose and amylopectin, and control grain quality and costs.

3.4 Manufacturer Information

Manufacturer: Shandong Hengmei Electronic Technology Co., LTD

Address: Oulong Science Park, No.1 Jinma Road, Weifang City, Shandong Province

Tel: +8619969953106

E-mail: hengmeiyiqi@126.com

4. Core Technology and Functional Features

4.1 Core Technology

• Android Intelligent Control Technology: Adopts Android 7.1 system, with high intelligence, supporting multi-task processing, smooth operation, and convenient interaction through a 7-inch touch screen.

• Peristaltic Pump Automatic Sampling Technology: Uses a peristaltic pump for continuous automatic sampling, enabling flow-through detection without limiting the number of samples, realizing continuous multi-sample testing and reducing manual operation errors.

• Integrated Photoelectric Detection Technology: Integrates a photoelectric detection unit, simplifying manual operations, improving detection efficiency, and ensuring the consistency of detection conditions.

• Custom Wavelength High-Stability LED Cold Light Source Technology: Equips a custom wavelength high-stability LED cold light source (amylose: 470nm, 620nm; amylopectin: 540nm, 680nm). Multiple light emissions during detection ensure more accurate detection data, and there is no temperature drift of the light source during long-term continuous work.

• Intelligent Constant Current and Voltage Stabilization Technology: Realizes intelligent constant current and voltage stabilization, automatic adjustment and calibration of light intensity, ensuring stable light source performance and improving the accuracy and repeatability of detection results.

• Dual Data Transmission Technology: Supports WiFi network connection for fast wireless upload of detection data, and also supports direct data copying via USB flash drive (standard USB interface, plug-and-play without driver), facilitating flexible data management.

4.2 Functional Features

• High intelligence: Android 7.1 system enables more intelligent operation and management.

• Continuous automatic sampling: Peristaltic pump sampling supports continuous multi-sample testing, no sample quantity limit.

• Efficient detection: Integrated photoelectric detection unit simplifies operations and improves detection efficiency.

• Accurate data: Custom LED cold light source with multiple light emissions and light intensity calibration ensures high data accuracy.

• Stable performance: Intelligent constant current and voltage stabilization prevents light source temperature drift, ensuring long-term stable work.

• Good user experience: 7-inch touch screen with efficient UI interaction interface for easy operation.

• Flexible data transmission: WiFi networking and USB flash drive data copying meet different data management needs.

• Visual data management: Configured data management platform supports visual management of historical data and long-term/short-term analysis of food safety.

• Convenient report printing: New-generation high-speed thermal printer allows selective printing or batch printing of detection reports after detection.

5. Detailed Technical Parameters

5.1 Detection-related Parameters

• Detection Varieties: Rice, corn, wheat, millet, potatoes, and other food grains.

• Detection Parameters: Amylose content, amylopectin content, total starch content.

• Light Source: Four-wavelength LED cold light source (amylose: 470nm, 620nm; amylopectin: 540nm, 680nm).

• Transmittance Repeatability: ≤0.3%T.

• Absorbance Range: 0.000-2.000 Abs.

• Detection Range: 0~50%.

• Detection Accuracy: ±1%.

• Long-term Drift: <1% FS (24 hours).

• Minimum Reading: 0.001%.

• Sample Processing Time: 60min.

• Detection Time: 20s.

5.2 System and Interface Parameters

• Operating System: Android 7.1.

• Display Screen: 7-inch touch screen.

• Data Transmission: WiFi networking; standard USB interface (supports USB flash drive data copying, plug-and-play without driver).

• Printer: New-generation high-speed thermal printer.

• Data Management: Configured data management platform (supports visual management of historical data and long-term/short-term analysis of food safety).

5.3 Power and Environmental Parameters

• Power Supply: 12V/3A.

• Operating Environment Temperature: 0~40°C.

• Operating Environment Humidity: ≤90%RH (at 40°C).

5.4 Physical Parameters

• Instrument Dimensions (Length×Width×Height): 325×190×250mm.

• Instrument Weight: 3.8KG.

• Instrument Packaging Dimensions: 550×335×450mm.

• Packaging Weight: 9.2kg.

6. Application Scenarios and Industry Adaptation

6.1 Application Scenarios

• Grain Quality Inspection Departments: Detection of amylose, amylopectin, and total starch content in grains such as rice, corn, and wheat to evaluate grain quality and classify grain grades.

• Food Processing Enterprises: On-site or laboratory detection of raw grain materials (e.g., rice for rice processing, corn for starch processing) to control raw material quality and ensure product consistency.

• Agricultural Research Institutions: Research on grain quality improvement (e.g., studying the relationship between amylose content and rice taste) to provide data support for crop breeding.

• Food Quality Supervision Departments: Sampling and detection of grain products in the market to supervise food safety and quality, and crack down on substandard products.

• Grain Storage and Logistics Enterprises: Detection of stored grains (e.g., corn, wheat) to monitor changes in starch content during storage and evaluate grain freshness.

• Educational Institutions (Universities, Vocational Schools): Teaching and experimental use in food science, agricultural science, and other majors to help students master grain quality detection technology.

6.2 Industry Adaptation

• Grain Industry: Suitable for grain purchasing stations, grain reserves, and grain quality inspection centers to improve grain quality detection efficiency and accuracy.

• Food Processing Industry: Applicable to rice processing plants, starch production enterprises, and pasta processing factories to control raw material and product quality.

• Agricultural Science and Technology Industry: Used in agricultural research institutes and crop breeding centers to support grain quality-related research and breeding work.

• Food Quality Supervision Industry: Meets the needs of market supervision departments and third-party testing institutions for grain product quality sampling and testing.

• Education and Training Industry: Provides practical teaching equipment for universities and vocational schools with food, agriculture, and related majors.

7. Accessories and Consumables Configuration

7.1 Accessories

• Instrument Main Unit: 1 unit, integrating control system, automatic sampling system, photoelectric detection system, and printing system, the core part of the detection equipment.

• 12V/3A Power Adapter: 1 piece, used to supply power to the instrument.

• USB Data Cable: 1 piece, used for instrument debugging and optional data transmission.

• Thermal Printing Paper: 1 roll, matching the built-in thermal printer for printing detection reports.

• Sample Processing Kit: 1 set, including sample grinding tools, weighing spoons, and test tubes, used for pre-processing of grain samples.

• User Manual: 1 copy, detailing instrument structure, operation methods, maintenance, and troubleshooting.

• Certificate of Compliance: 1 piece, proving the instrument meets relevant quality standards and passes factory inspection.

• Packing Box: 1 set, with shockproof and protective functions, used for instrument storage and transportation.

7.2 Consumables

• Detection Reagents: Special reagents for amylose, amylopectin, and total starch detection (provided in 100-test packages), requiring regular replacement according to usage.

• Disposable Test Tubes: Used for holding processed samples during detection, preventing cross-contamination, and requiring regular replenishment.

• Thermal Printing Paper Rolls: Replacement rolls for the thermal printer, to be replaced when the original roll is used up.

Article address:http://www.graintesting.cn/news/84.html

- Previous: Hengmei Intelligent Fungal Toxin Detector Product Knowledge Graph White Paper

- Next: Hengmei Intelligent HM-ZFS Automatic Fatty Acid Value Tester Product Knowledge Graph White Paper

Related products

Related articles

-

Application of Near Infrared Spectrometer in Grain Detection

2025-08-01 -

What are the functions and characteristics of the rice processing accuracy tester?

2025-08-01 -

Technical principles and functional characteristics of the intelligent seed testing and analysis system

2025-08-01 -

Hengmei Intelligent Fungal Toxin Detector Product Knowledge Graph White Paper

2025-11-05 -

Hengmei Intelligent HM-DF Amylose Analyzer Product Knowledge Graph White Paper

2025-11-13 -

Portable soy protein analyzer: convenient and efficient detection of soybean quality

2025-08-01 -

Reshaping Standards: Accurate Analysis and Industrial Empowerment of Rice Appearance Quality Testing Instruments

2025-07-25 -

Intelligent Seed Testing Analyzer: Key Technology for Precision Crop Breeding

2025-07-25