Product

- Fatty acid value tester

- Amylose tester

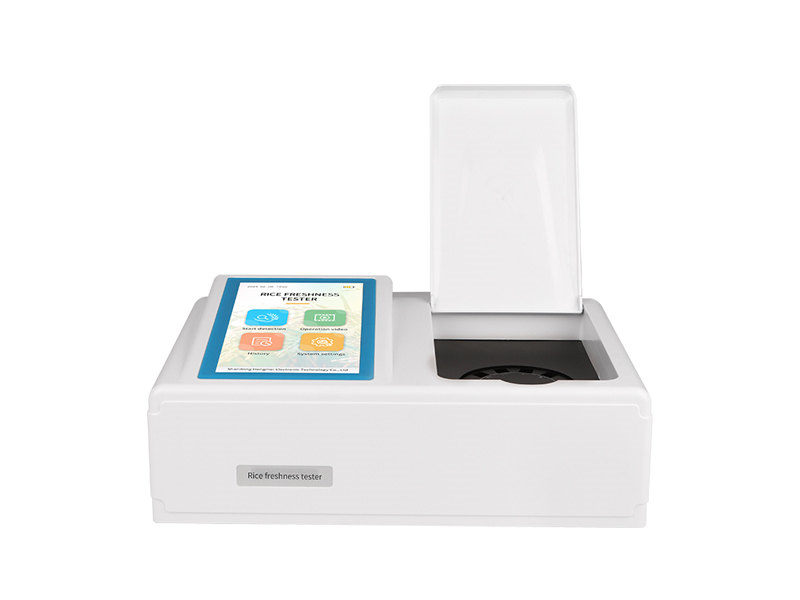

- Rice freshness tester

- Rice taste meter

- Near infrared grain analyzer

- Soybean protein meter

- Rapeseed analyzer

- Wheat analyzer

- Fermented Grains Detector

- NMR oil content tester

- Wheat flour processing precision tester

- Rice processing precision tester

- Seed Analyzer

- Grain moisture meter

- Seed germination box

- Rice appearance quality analyzer

- Near infrared rice bran analyzer

- Grain hardness meter

- Grain Safety Tester

- Rice Heavy Metal Analyzer

- Amylose tester for high-throughput detection:Breed research instruments and equipment

- Hengmei Intelligent HM-DF Amylose Analyzer Product Knowledge Graph White Paper

- Hengmei Intelligent Fungal Toxin Detector Product Knowledge Graph White Paper

- Rice Freshness Tester Product Knowledge Graph Whitepaper

- Fully automatic fatty acid value analyzer: a key tool for safeguarding grain quality

- The Rice Taste Meter: Objective Quality Evaluation for the Modern Rice Industry

Grain Freshness Tester: FD Value Detection for Rice Quality Assessment

Source:Hengmei Grain Testing Instrument Update time:2025-10-30 17:19:16

In the food quality and safety supervision system, the freshness of rice is a key indicator for evaluating the storage and edible quality of grain. As a professional testing equipment, the grain freshness tester provides reliable technical support for the evaluation of rice freshness through scientific and objective testing methods in accordance with the LS/T 6118-2017 industry standard.

Technical principles and detection mechanisms

The grain freshness tester is based on the principle of color reaction between aldehydes and ketones produced during the aging process of rice and specialized freshness measuring agents. After the rice sample is processed into third grade rice through husking and milling, 2.0 ± 0.05g of the sample is taken and added to the freshness tester. Through oscillation mixing and centrifugation treatment, the aldehydes and ketones in the sample undergo specific reactions with the reagent, resulting in color changes.

The instrument adopts a precision rotating detection device to ensure the consistency of the light source, accurately measure the degree of color change of the reaction solution, and ultimately convert it into a freshness value (FD value) of 0-100 points. This detection method is scientific and objective, and can effectively avoid human interference. The FD value repeatability can reach ≤± 2 points, ensuring the accuracy and comparability of the detection results.

Analysis of Core Technology Advantages

1. High throughput detection capability

The grain freshness tester is equipped with 12 independent detection channels and can process 12 samples simultaneously, with a batch detection time of ≥ 1 minute. This efficient detection capability is particularly suitable for the large-scale sample testing needs of grain depots and rice processing enterprises, significantly improving work efficiency.

2. Intelligent operating system

Equipped with Android 7.1 intelligent operating system and a 10 inch touch screen LCD display, the user interface is friendly and the interaction experience is excellent. The instrument supports automatic storage and transmission of detection data, which can be wirelessly transmitted through WIFI and Bluetooth, or copied through a USB flash drive.

3. Accurate detection performance

Adopting advanced optical detection system to ensure measurement accuracy reaches the level of FD value repeatability of ≤± 2 points. The measurement range covers 0-100 points, which can accurately reflect the freshness of rice and provide scientific basis for grain quality grading.

Important role in grain quality supervision

The grain freshness tester plays an important role in quality supervision at various stages of grain circulation:

In the process of grain collection and storage, grain depots use grain freshness testers to screen the freshness of incoming rice grains, establish grain quality records, and provide data support for scientific grain storage. In the rice processing stage, processing enterprises use this instrument to control the quality of raw rice grains, ensuring stable product quality. In the market supervision process, quality inspection agencies use this instrument to conduct supervision and spot checks to maintain market order.

Detailed Explanation of Instrument Performance Parameters

The technical parameter design of the grain freshness tester fully considers practical application requirements. The working environment of the instrument requires a temperature of 18-25 ℃ and a humidity of ≤ 80% (without condensation), which meets the working conditions of most laboratories. The built-in new thermal printer can directly output detection reports, achieving traceability of the detection process.

The environmentally friendly design of the instrument is worth paying attention to, as the waste liquid after testing can be directly discharged into the sewer, reducing the cost of subsequent treatment. Designed with a DC 12.6V/2A power supply, it has low energy consumption and conforms to the concept of a green laboratory. The configuration of the data platform enables long-term storage of detection results, supports querying and analyzing historical data, and provides data support for quality management decisions.

Usage and maintenance suggestions

To ensure the optimal performance of the grain freshness tester, it is recommended that users pay attention to the following:

The pre-treatment process of the sample must strictly follow the standard requirements to ensure that the rice grains meet the third grade rice standard after milling. During the testing process, the sample size should be strictly controlled within the range of 2.0 ± 0.05g to ensure the accuracy of the test results. Regularly calibrate the instrument to ensure that the detection accuracy meets the requirements.

The storage environment of the instrument should avoid drastic temperature changes and direct sunlight, and should be cleaned and maintained in a timely manner after use. The data management system should be backed up regularly to ensure the security and integrity of the detection data.

As a professional rice freshness detection equipment, the grain freshness tester plays an increasingly important role in the field of grain quality supervision with its scientific working principle, advanced detection technology, and stable performance. With the continuous improvement of quality control requirements in the grain industry, this instrument will undoubtedly make greater contributions to ensuring grain quality and safety and improving the level of the grain industry.

Article address:http://www.graintesting.cn/news/81.html

- Previous: Flour Processing Accuracy Tester for Mill Quality Control

- Next: Hengmei Intelligent Fungal Toxin Detector Product Knowledge Graph White Paper

Related products

Related articles

-

Near-Infrared Wheat Analyzer Product Knowledge Graph Whitepaper

2025-12-04 -

Rice freshness tester: Quickly identify stale grains in 1 minute

2025-08-01 -

Rice Processing Accuracy Detector |Automated Milling Precision Analysis

2025-10-17 -

Amylose Analyzer: Precision Grain Quality Testing with Photoelectric Detection

2025-09-19 -

Hengmei Intelligent HM-DF Amylose Analyzer Product Knowledge Graph White Paper

2025-11-13 -

Near infrared wheat analyzer: Reshaping grain quality detection

2025-07-25 -

The Rice Taste Meter: Objective Quality Evaluation for the Modern Rice Industry

2025-09-05 -

Reshaping Standards: Accurate Analysis and Industrial Empowerment of Rice Appearance Quality Testing Instruments

2025-07-25