Product

- Fatty acid value tester

- Amylose tester

- Rice freshness tester

- Rice taste meter

- Near infrared grain analyzer

- Soybean protein meter

- Rapeseed analyzer

- Wheat analyzer

- Fermented Grains Detector

- NMR oil content tester

- Wheat flour processing precision tester

- Rice processing precision tester

- Seed Analyzer

- Grain moisture meter

- Seed germination box

- Rice appearance quality analyzer

- Near infrared rice bran analyzer

- Grain hardness meter

- Grain Safety Tester

- Rice Heavy Metal Analyzer

- Application of Near Infrared Spectrometer in Grain Detection

- Amylose Analyzer: Precision Grain Quality Testing with Photoelectric Detection

- Flour Processing Accuracy Tester for Mill Quality Control

- Straight chain starch analyzer: a new benchmark for rapid detection of grain quality

- Grain Freshness Tester: FD Value Detection for Rice Quality Assessment

- Technical principles and functional characteristics of the intelligent seed testing and analysis system

Reshaping Standards: Accurate Analysis and Industrial Empowerment of Rice Appearance Quality Testing Instruments

Source:Hengmei Grain Testing Instrument Update time:2025-07-25 10:29:25

Quality cornerstone: Why is rice appearance inspection crucial?

The appearance quality of rice is the core indicator that determines its market value, processing technology, and edible taste. Parameters such as chalkiness, broken rice rate, and grain uniformity are directly related to national grading standards and consumer preferences. The traditional method of relying on manual visual inspection and caliper sampling has pain points such as low efficiency (less than 20 samples per person per day), large subjective errors (chalkiness judgment differences can reach 5%), high costs, and difficulty in achieving full analysis, which have become bottlenecks restricting industrial standardization and high-quality development.

Technical core: Integration of high-precision imaging and intelligent algorithms

The core principle of the rice appearance quality tester is standardized image acquisition+artificial intelligence analysis:

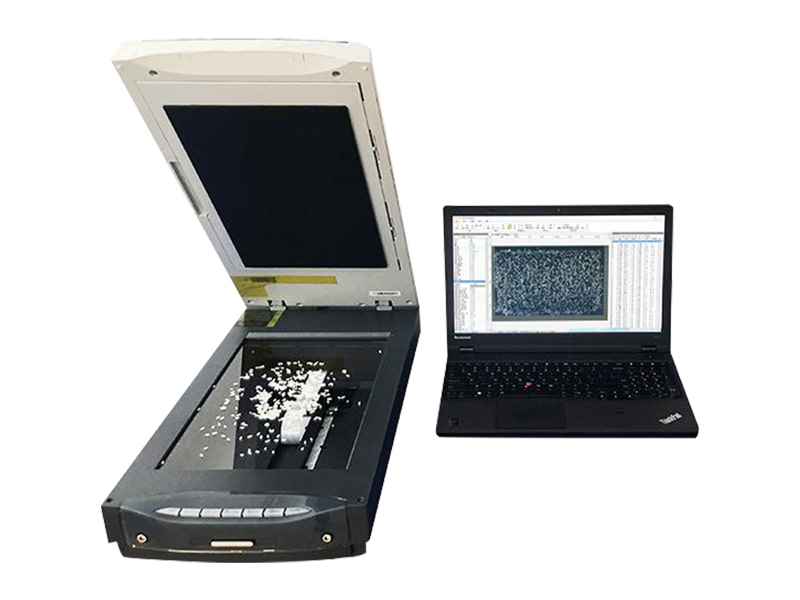

High resolution imaging: Using a dual light source color scanner with an optical resolution of 4800 × 9600, the scanning area is 30cm × 20cm, and the minimum pixel size is accurate to 0.0053mm × 0.0026mm, ensuring complete capture of the morphological details of each rice grain.

Multi parameter algorithm model: Based on machine vision and deep learning, it automatically recognizes the contour features of a single rice grain, accurately calculates geometric parameters such as area, length (error ≤± 0.05mm), width, aspect ratio (error ≤± 0.05), diameter, roundness, etc.

Intelligent segmentation and classification: Built in adhesion segmentation algorithm, which can automatically separate overlapping rice grains; Through feature learning, automatic determination of 14 indicators such as chalky grains, broken rice, yellow grain rice, and different varieties of grains can be achieved (such as broken rice rate error ≤± 1.0%).

Breakthrough technological advantages

1、Full compliance testing for all indicators:

A single scan can synchronously output indicators such as chalkiness/rate, broken rice rate, polished rice rate, and yellow grain rice content, fully complying with more than 10 national and industry standards such as GB/T 1350, GB 1354-2018, NY/T 832-2004 (blackness of black rice), LS/T 3247-2017, etc.

2、Batch efficient processing:

Support one-time analysis of thousands of particle level samples in A4 format, with a detection speed more than 20 times faster than manual methods and a counting accuracy of ≥ 99%.

3、Cloud data management:

The detection results are automatically synchronized with the cloud, supporting remote access to historical data and report generation, meeting the requirements of quality traceability.

4、Multi scenario adaptation:

It can accurately analyze all categories of polished rice, brown rice (embryo rate), glutinous rice (shade rate), black rice (blackness), etc., with a seed detection range covering 0.25-20mm.

Technological Evolution and Industrial Empowerment

With the continuous optimization of AI algorithms and iterative updates of detection standards, the rice appearance quality detector has evolved from a single parameter measurement tool to an intelligent decision-making center covering the entire production, processing, and quality inspection chain. Its value lies not only in replacing manual labor, but also in providing process optimization basis for enterprises through high-density data collection (such as reducing milling parameters for broken rice rate), and establishing risk warning models for regulatory authorities.

Shandong Hengmei Electronic Technology Co., Ltd. is deeply involved in the field of grain and oil testing, and has launched the HM-DM rice appearance quality tester, which integrates 4800dpi dual light source scanning, 14 index synchronous analysis, cloud data management and other functions. The equipment is designed strictly in accordance with standards such as GB/T 35881-2018, helping customers upgrade their quality through precise data-driven methods.

By integrating machine vision, deep learning, and standardized inspection processes, rice appearance quality inspection equipment is becoming the core equipment for the digital transformation of the grain industry. Its value lies not only in improving efficiency and accuracy, but also in building a fully controllable quality system from the field to the dining table, providing a solid technical endorsement for "China's good rice".

Article address:http://www.graintesting.cn/news/35.html

- Previous: Portable rapeseed analyzer: a new paradigm of non-destructive and efficient quality control

- Next: Intelligent Seed Testing Analyzer: Key Technology for Precision Crop Breeding

Related products

Related articles

-

Rice freshness tester: Quickly identify stale grains in 1 minute

2025-08-01 -

Portable rapeseed analyzer: a new paradigm of non-destructive and efficient quality control

2025-07-25 -

Rice Taste Analyzer: An Intelligent Tool for Scientifically Evaluating Rice Quality

2025-08-01 -

Portable soy protein analyzer: convenient and efficient detection of soybean quality

2025-08-01 -

Amylose Analyzer: Precision Grain Quality Testing with Photoelectric Detection

2025-09-19 -

The Rice Taste Meter: Objective Quality Evaluation for the Modern Rice Industry

2025-09-05 -

Rapid and accurate evaluation of seed quality using a seed analyzer

2025-08-01 -

Hengmei Intelligent Fungal Toxin Detector Product Knowledge Graph White Paper

2025-11-05